M59x30-H_PM52LN

Stall torque from 1382,3Nm to 3,32Nm

Applications for the electric motor M59x30-H_PM52LN

The M59x30-H_PM52LN planetary gear motors are used in linear actuators and in automatisms of various kind.

M59x30-H_PM52LN

The M59x30-H electric motors are equipped with filter and one or two Hall sensors. The PM52LN planetary gearboxes have both toothed wheels and housing made of metal.

The Hall sensors supply a signal which allows to count the number of rotations made by the motor. With two Hall sensor it is possible to determine also the rotation direction of the electric motor.

The filter, generally made of an LC-circuit, allows the electric motors to be tested in compliance with the EMC norms.

In the technical data-sheet it is possible to select the circuit with one or two Hall sensors and to request a particular set of cables or a special output gear shaft, different from the represented standard, by indicating them in the requirements form.

In the “Electric Data” table is indicated the range of working voltages of M59x30-H_PM52LN planetary gear motors and are listed the performances for the most commonly used voltages, 12V and 24V.

The interactive curve allows to choose the required performances by selecting the power voltage, no-load speed and the gear ratio at one, two or three stages.

Stages data

Stage

Stage 1

Stage 2

Stage 3

Perm. output torque

Stage 1

4 Nm

Stage 2

12 Nm

Stage 3

25 Nm

Reduction ratios range

Stage 1

4:1

÷13:1

Stage 2

14:1

÷89:1

Stage 3

50:1

÷601:1

Max Backslash

Stage 1

0.7°

Stage 2

0.75°

Stage 3

0.8°

Reduction ratios range

Stage 1

-30°C

to120°C

Stage 2

-30°C

to120°C

Stage 3

-30°C

to65°C

Max. load, radial (Mid output shaft)

Stage 1

200 N

Stage 2

320 N

Stage 3

450 N

Max. load, axial

Stage 1

60 N

Stage 2

100 N

Stage 3

150 N

Max. perm. fitting pressure

Stage 1

500 N

Stage 2

500 N

Stage 3

500 N

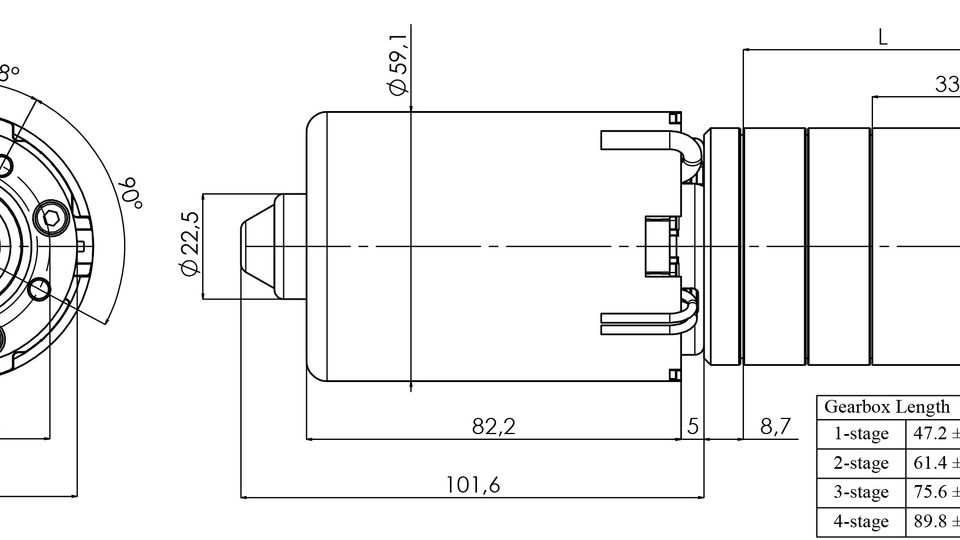

Reduction ratios range

Stage 1

73.1

±0,5

Stage 2

87.25

±0,5

Stage 3

101.4

±0,5

Weight (approx.)

Stage 1

0.7 Kg

Stage

Stage 1

Stage 2

Stage 3

Standard nominal voltage

12V

24V

12V

24V

12V

24V

No load speed - N0 [Rpm]

Stage 1

12V

1750

÷192

24V

1750

÷192

Stage 2

12V

500

÷28

24V

500

÷28

Stage 3

12V

140

÷4.16

24V

140

÷4.16

No load current - I0 [A]

Stage 1

12V

2.2

÷0.8

24V

1.1

÷0.4

Stage 2

12V

2.2

÷0.8

24V

1.1

÷0.4

Stage 3

12V

2.2

÷0.8

24V

1.1

÷0.4

Nominal speed - Nn [Rpm]

Stage 1

12V

1701

÷177.2

24V

1701

÷177.2

Stage 2

12V

486

÷25.9

24V

486

÷25.9

Stage 3

12V

136

÷3.83

24V

136

÷3.83

Nominal torque - Mn [Nm]

Stage 1

12V

0.26

÷0.83

24V

0.26

÷0.83

Stage 2

12V

0.9

÷5.7

24V

0.9

÷5.7

Stage 3

12V

3.2

÷38.4

24V

3.2

÷38.4

Nominal current - In [A]

Stage 1

12V

6

÷2

24V

3

÷1

Stage 2

12V

6

÷2

24V

3

÷1

Stage 3

12V

6

÷2

24V

3

÷1

Nominal power - Pn [W]

Stage 1

12V

45.6

÷15.5

24V

45.6

÷15.5

Stage 2

12V

45.6

÷15.5

24V

45.6

÷15.5

Stage 3

12V

45.6

÷15.5

24V

45.6

÷15.5

Stall torque - Ms [Nm]

Stage 1

12V

29.9

÷3.32

24V

29.9

÷3.32

Stage 2

12V

204.7

÷11.6

24V

204.7

÷11.6

Stage 3

12V

1382.3

÷42.3

24V

1382.3

÷42.3

Starting current - Is [A]

Stage 1

12V

132

÷17

24V

66

÷8.5

Stage 2

12V

132

÷17

24V

132

÷17

Stage 3

12V

132

÷17

24V

66

÷8.5

Max power - Pmax [W]

Stage 1

12V

420

÷53

24V

415

÷53

Stage 2

12V

420

÷53

24V

415

÷53

Stage 3

12V

420

÷53

24V

415

÷53

Max efficiency - ηmax [N]

Stage 1

12V

81

÷61

24V

81

÷61

Stage 2

12V

81

÷61

24V

81

÷61

Stage 3

12V

81

÷61

24V

81

÷61

Mechanical data

Type of duty

S1

Weight

0.75