M42/39-H_PK42

Stall torque from 234,0Nm to 0,92Nm

Applications for the electric motor M42/39-H_PK42

The most common applications for the M42/39-H_PK42 Dc electric planetary gear motors are generally within the automotive and the linear actuators markets.

M42/39-H_PK42

The M42/39-H electric motors are equipped with EMC filter and with encoder, consisting of a magnetic ring and a circuit with one or two Hall sensors.

The PK42 planetary gearboxes have both toothed wheels and the toothed peripheral crown made by plastic.

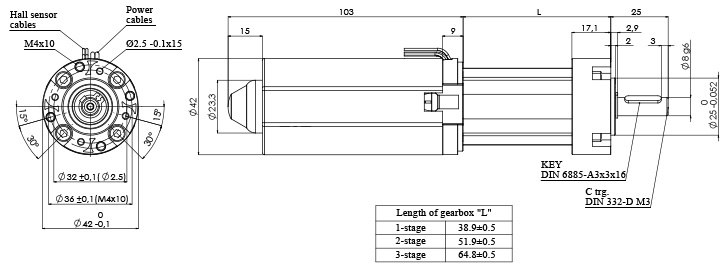

In the technical interactive datasheet is available the motor drawing and it’s possible to choose the gearbox shaft and the EMC filter type.

About the encoder, it’s possible to select the type and the number of the Hall sensors on the circuit, the number of poles of the magnetic ring and for each combination sensors-magnetic ring is represented the outcoming signal.

To define the characteristic curve with the preferred performances it’s sufficient to write power voltage and no-load speed and gear ratio in one, two or three stages within the indicated, allowed ranges or, more simply, it’s available the pre-defined characteristic curve.

Every selected option is saved automatically in the below enquiry form, in witch it’s possible to load files.

In the chart “Electrical Data” are indicated the performances values for the most commonly used voltages, 12V ad 24V.

Stages data

Stage

Stage 1

Stage 2

Stage 3

Perm. output torque

Stage 1

0.8 Nm

Stage 2

2 Nm

Stage 3

4 Nm

Reduction ratios range

Stage 1

4:1

÷7:1

Stage 2

14:1

÷46:1

Stage 3

51:1

÷308:1

Max Backslash

Stage 1

1.7°

Stage 2

1.75°

Stage 3

1.8°

Reduction ratios range

Stage 1

-15°C

to65°C

Stage 2

-15°C

to65°C

Stage 3

-15°C

to65°C

Max. load, radial (Mid output shaft)

Stage 1

15 N

Stage 2

30 N

Stage 3

45 N

Max. load, axial

Stage 1

5 N

Stage 2

10 N

Stage 3

30 N

Max. perm. fitting pressure

Stage 1

150 N

Stage 2

150 N

Stage 3

150 N

Reduction ratios range

Stage 1

59.8

±0,5

Stage 2

72.8

±0,5

Stage 3

85.9

±0,5

Weight (approx.)

Stage 1

0.15 Kg

Stage

Stage 1

Stage 2

Stage 3

Standard nominal voltage

12V

24V

12V

24V

12V

24V

No load speed - N0 [Rpm]

Stage 1

12V

2000

÷357

24V

2000

÷357

Stage 2

12V

571

÷54

24V

571

÷54

Stage 3

12V

157

÷8.1

24V

157

÷8.1

No load current - I0 [A]

Stage 1

12V

1.9

÷0.6

24V

0.9

÷0.3

Stage 2

12V

1.9

÷0.6

24V

0.9

÷0.3

Stage 3

12V

1.9

÷0.6

24V

0.9

÷0.3

Nominal speed - Nn [Rpm]

Stage 1

12V

1935

÷320

24V

1870

÷283

Stage 2

12V

553

÷48.7

24V

534

÷43

Stage 3

12V

152

÷7.3

24V

146.6

÷6.4

Nominal torque - Mn [Nm]

Stage 1

12V

0.1

÷0.18

24V

0.2

÷0.35

Stage 2

12V

0.35

÷1.15

24V

0.7

÷2.3

Stage 3

12V

1.28

÷7.7

24V

2.55

÷15.4

Nominal current - In [A]

Stage 1

12V

3.3

÷1

24V

2.4

÷0.75

Stage 2

12V

3.3

÷1

24V

2.4

÷0.75

Stage 3

12V

3.3

÷1

24V

2.4

÷0.75

Nominal power - Pn [W]

Stage 1

12V

20.2

÷5.6

24V

39

÷10.3

Stage 2

12V

20.2

÷5.6

24V

39

÷10.3

Stage 3

12V

20.2

÷5.6

24V

39

÷10.3

Stall torque - Ms [Nm]

Stage 1

12V

5.32

÷0.92

24V

5.32

÷0.92

Stage 2

12V

35

÷3.22

24V

35

÷3.22

Stage 3

12V

234

÷11.7

24V

234

÷11.7

Starting current - Is [A]

Stage 1

12V

47

÷4.8

24V

23.5

÷2.4

Stage 2

12V

47

÷4.8

24V

23.5

÷2.4

Stage 3

12V

47

÷4.8

24V

23.5

÷2.4

Max power - Pmax [W]

Stage 1

12V

160

÷15.2

24V

160

÷15.2

Stage 2

12V

160

÷15.2

24V

160

÷15.2

Stage 3

12V

160

÷15.2

24V

160

÷15.2

Max efficiency - ηmax [N]

Stage 1

12V

78.5

÷51.5

24V

78.5

÷51.5

Stage 2

12V

78.5

÷51.5

24V

78.5

÷51.5

Stage 3

12V

78.5

÷51.5

24V

78.5

÷51.5

Mechanical data

Gear ratio

4

÷7

Type of duty

S1

Weight

0.5