Quality and flexibility

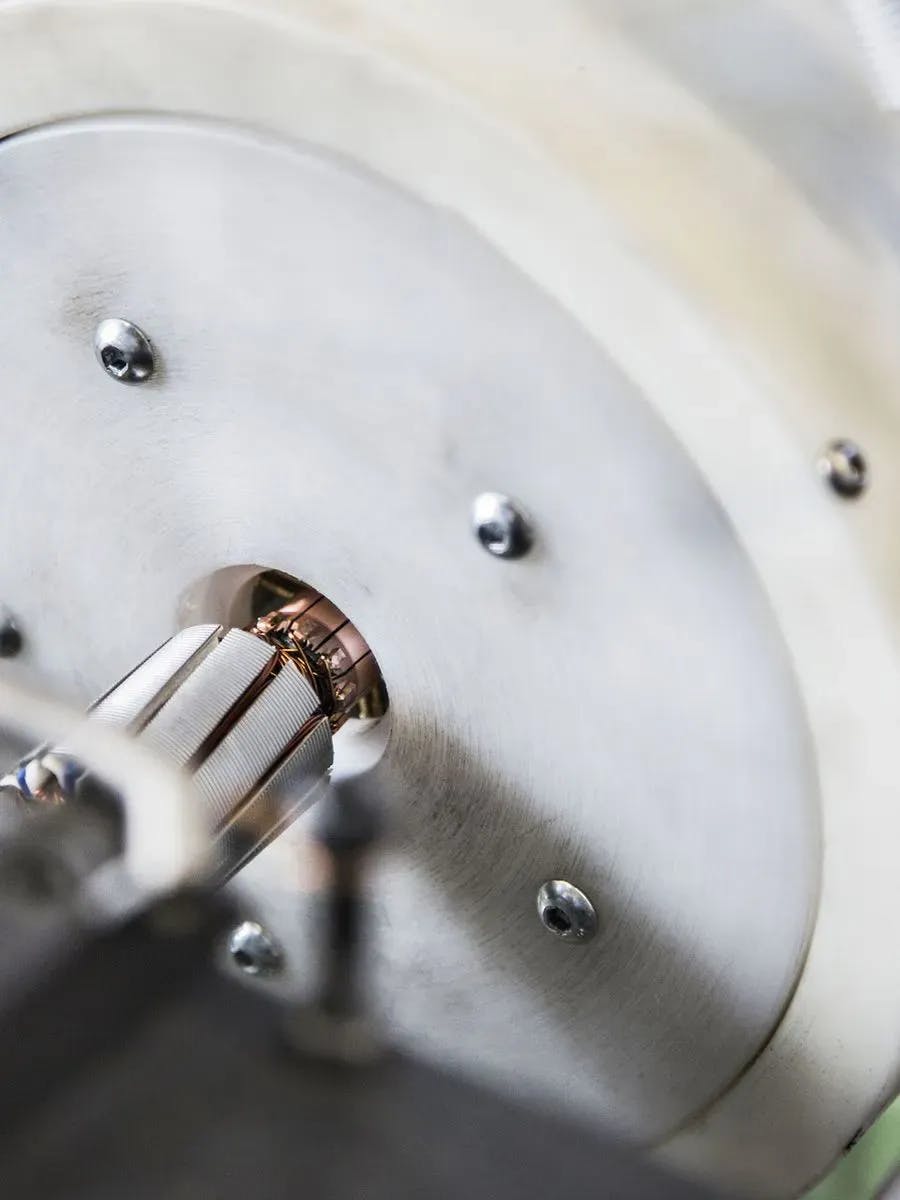

The reliability of a Dc electric motor includes many requires. The first require is a safe production, which is a guarantee of the reliability.

The first require

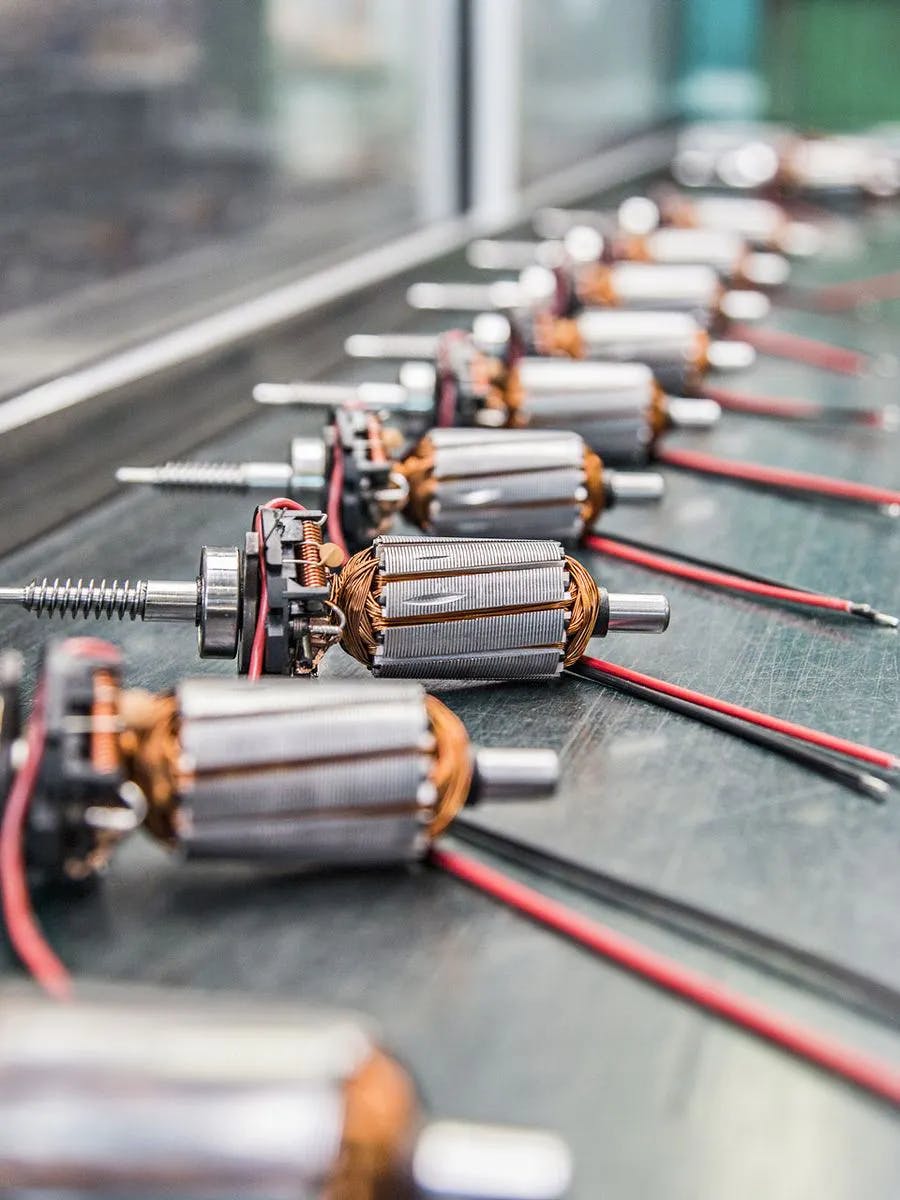

Then, the other important requirements of a Dc motor, a DC gear motor or a Dc planetary gear motor, are low noise, mainly connected to the brushes noise, absence of vibrations and mechanical reliability.

Quality is researched trough the selection of each single component of the motor and during the whole production cycle. Ride is the ideal partner to face new challenges thanks to process reliabilityand to electric and automatic performances.

Production flexibility

The way the automation is devised, allows to satisfy every special request.

The automation of production and the experience in designing special project-based motors reduces to a minimum possible human mistakes or imperfections during the assembly. Every test guarantees the correct functioning and the reliability of the motors, which presents different constructive characteristics.

The experience in designing and the managing philosophy of production developed in Ride allow to realize inside the production cycle of electric motors also non-standard motors and gear motors, maintaining all the while the reliability of the processes and of the product.

Discover our motors

Direct Current Electric Motors

Ride crafts DC motors and gearmotors for every industry, ensuring tailored performance and reliability.